Description

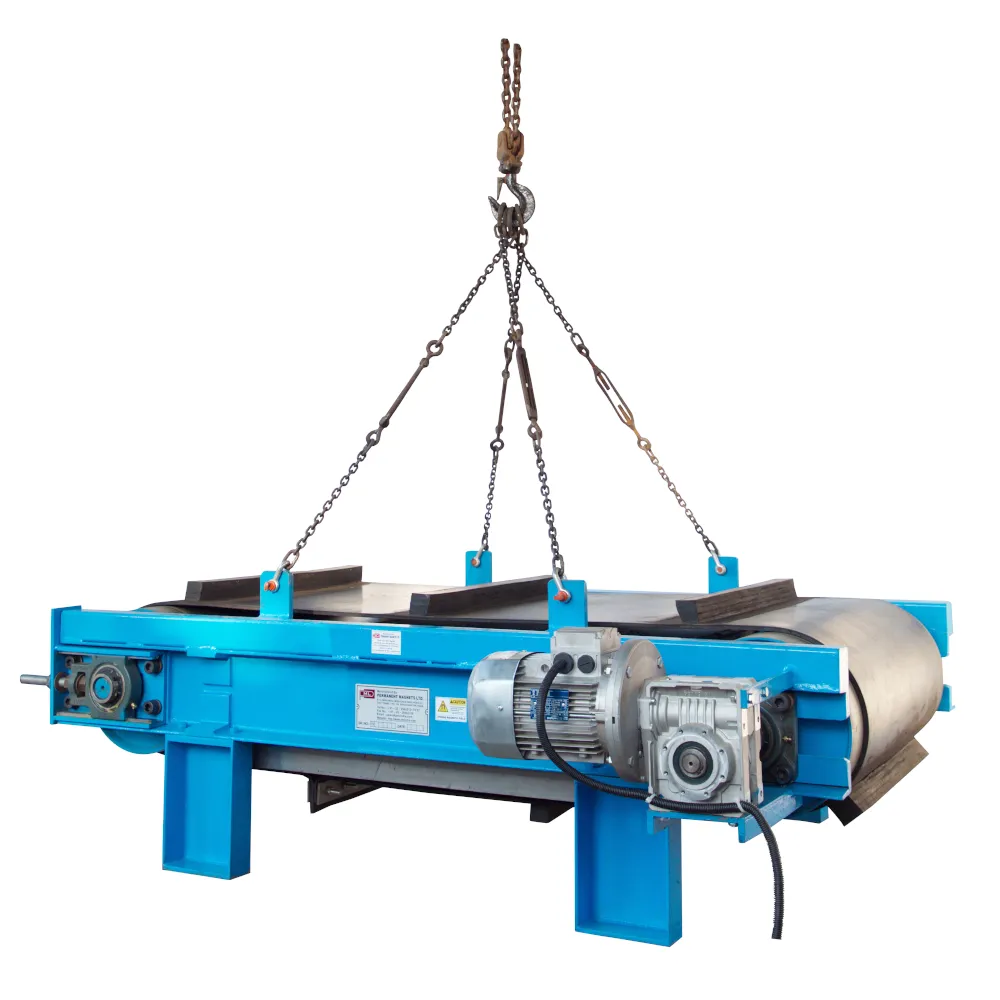

Cross Belt Magnetic Separators offer an efficient, self-cleaning solution for the continuous removal of ferrous contaminants from materials flowing on conveyor belts. The system utilizes a powerful overhead suspended plate magnet housed in a robust, industrial conveyor operating in an inverted position, ensuring effective separation of metal particles.

Features:

- Self-Cleaning Magnetic Conveyor: Continuous removal of ferrous materials.

- High-Strength Magnet: Deep, concentrated magnetic field for superior separation.

- Rugged Design: Built for 100% duty cycle and harsh industrial environments.

- Low Maintenance: Easy installation and operation with minimal upkeep.

- Energy Efficient: Reduces operational costs.

- Customizable Options:

- Easy access for inspection and maintenance.

- Trolley and cable suspension options.

- Simple belt alignment via Plummer block arrangements.

- Custom paint options available.

Magnet Features:

- Permanent Magnet Types: Strontium Ferrite or NdFeB (Rare Earth).

- Magnetic Strength: Up to 700 Gauss at a distance for effective separation.

- Drive System: Fitted with IP54 electric high-performance motors and flexible coupling.

Models and Dimensions:

| Medium intensity Permanent Magnetic Cross Belt Separator: Strontium Ferrite Magnets | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model No. | Length A (mm) | Width B (mm) | Height c (mm) | Magnet Type | Magnetic Strength (450 Gauss) at distance | Geared Motor (KW) | Weight (Kg) | Effective Conveyor Width Allowed(mm) |

| CPM 50F | 1722 | 1194 | 511 | Ferrite | @150 | 2.2kw | 691 | 500 |

| CPM 65F | 1872 | 1344 | 511 | Ferrite | @200 | 2.2kw | 936 | 650 |

| CPM 80F | 2022 | 1494 | 511 | Ferrite | @250 | 2.2kw | 1151 | 800 |

| CPM 100F | 2222 | 1694 | 511 | Ferrite | @250 | 2.2 Kw | 1541 | 1000 |

| CPM 120F | 2422 | 1894 | 511 | Ferrite | @250 | 2.2 Kw | 1833 | 1200 |

| High Intensity Permanent Magnetic Cross Belt Separator: NdFeB (Rare Earth) Magnets | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model No. | Length A (mm) | Width B (mm) | Height C (mm) | Magnet Type | Magnetic strength (700 Gauss) at distant | Geared Motor | Weight (Kg) | Effective conveyor belt width allowed (mm) |

| CPM 50 | 1722 | 1194 | 511 | Rare earth | @150 | 2.2kw | 665 | 500 |

| CPM 65 | 1872 | 1344 | 511 | Rare earth | @200 | 2.2kw | 840 | 650 |

| CPM 80 | 2022 | 1494 | 511 | Rare earth | @250 | 2.2kw | 1034 | 800 |

| CPM 100 | 2222 | 1694 | 511 | Rare earth | @250 | 2.2kw | 1370 | 1000 |

| CPM 120 | 2422 | 1894 | 511 | Rare earth | @250 | 2.2kw | 1670 | 1200 |

Construction:

- Magnetic System: CAD optimized Strontium Ferrite Ceramic or Rear Earth Permanent Magnetic system is mounted onto heavy-duty back plate and encased in stainless steel to obtain maximum magnetic flux across the flowing material underneath

- Electric Drive: Shaft mounted worm geared motor unit, fitted with IP54 electric high performance Non Geared Motors, connected to drive pulley via a flexible coupling. Power Supply : 440 V, 3 ph, 50 Hz

- Separator Belt: Heavy Duty 3-ply rubber belt 10.5mm in thickness, (4mm rubber anti-wear rubber on the upper, 1.5mm thick anti-wear rubber on lower, 4 plies of high-quality thread at the center). These belts have been vulcanized endless and travel at a speed of 1.5 m/s

- Bearings: Sealed for life pillow block bearings

- Pulleys: Fabricated mild steel with crowned face, fitted with slipper plates for ease of belt tension and tracking to increase belt life

- Guarding: Full length stainless steel guard fitted on the side of the overband to prevent access to nipping points and prevent belt damage due to product entrapment

- Support Frame: Welded construction provided with eyebolt for customers suspension slings

- Finish: All steel parts have one coat primer and two coats of high performance alkyd enamel

General Information:

CPM Series Cross Belt Magnetic Separators are used to remove tramp iron from conveyed materials by pulling the tramp upwards through the material against the force of gravity. They are very powerful magnets and are generally suspended above conveyor belts. Magnetic separation with belt pulley. Permanent magnet for belt conveyor.

Incorporated is a motor-driven magnetic conveyor belt running across the face of the magnet, continuously moving the collected material away from the magnetic field. The removed material falls away from the belt once it leaves the magnetic field, making it a self cleaning suspended magnetic conveyor belt separator.

It must be stressed that overhead magnets are not metal detectors, and they will only operate on magnetic materials. They will not react to authenticate steels or non-ferrous items.

Medium Intensity Permanent Magnetic Cross Belt Separators are used where the material to be separated is large enough to get acted upon by medium magnetic fields from large distances. These separators find ease in picking up large ferrous material from around 200mm depth. However if the material size is smaller and the burden depth is larger, these separators become inefficient.

High Intensity Permanent Magnetic Cross Belt Separators are employed at locations where separation of ferrous material is required from a distance for around 300 mm. This type of separator is useful in picking p bolts and nuts, channels, angles, and metal pieces from distances.

Performance Curve For A Typical Permanent Magnetic Cross Belt Separator

General experimental tests with M16x50 Bolt Attraction Distance (free state)

| Cross Belt Separator - Maximum Tramp Iron Attraction Distance Chart | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sr no. | Tramp Iron particle | Size in mm | Weight | Maximum Attraction distance in Inches | ||||

| CPM-50 | CPM-65 | CPM-80 | CPM-100 | CPM-120 | ||||

| 1 | Paper clip | 30 mm | 0.6 gm | 13 | 13.5 | 14 | 14.5 | 14.5 |

| 2 | Stapler pin | 10 mm | 0.016 gm | 11 | 12 | 14 | 14.5 | 14.5 |

| 3 | Nail | DIA 2 X 45 L | 1.16 gm | 12 | 13 | 14 | 14 | 17 |

| 4 | Spanner | 8,9 | 20 gm | 12 | 12 | 12.5 | 16 | 16 |

| 5 | Spanner | 18,19 | 120 mg | 11 | 12 | 12.5 | 16 | 16 |

| 6 | Spanner | 20,24 | 200gm | 11 | 11.5 | 12 | 15 | 15 |

| 7 | Spanner | 33,37 | 500 gm | 11 | 11.5 | 12 | 15 | 15 |

| 8 | Bolt | M10 x 100 L | 50 gm | 10 | 12 | 13 | 16 | 16 |

| 9 | Bolt | M20 x 100 L | 250 gm | 6.5 | 8 | 9 | 9 | 9.5 |

| 10 | Bolt | M16 x 60 | 100 gm | 8 | 10 | 11 | 11 | 12 |

| 11 | Nut | M16 | 10 gm | 6.5 | 8 | 9 | 9.5 | 9.5 |

| 12 | Nut | M8 | 5gm | 5 | 6.5 | 7 | 7.5 | 9 |

| 13 | Washer | OD 17 X ID 9 X 1.5 THK | - | 5 | 9 | 10 | 10 | 10.5 |

| 14 | Round M.S. Piece | Dia 23 x 2 THK | - | 7 | 7.5 | 8 | 12 | 12 |

| 15 | Round M.S. Piece | Dia 30 x 1.5 THK | - | 8.5 | 9.5 | 10 | 10 | 11 |

| 16 | Std. weight | - | 500gm | 5.5 | 6 | 6.5 | 7 | 7 |

| 17 | Std. weight | - | 1 kg | 6 | 7 | 7.5 | 7.5 | 7.5 |

| 18 | Std. weight | - | 2kg | 7 | 7.5 | 7.5 | 8 | 8 |

| 19 | Std. weight | - | 5kg | 7 | 7.5 | 8 | 9 | 9 |

| 20 | M.S .angle | 770 L X 80 W X 40 H | 1.5kg | 11 | 13 | 15 | 16 | 18 |

| 21 | Channel | 700 L X 50 W X 50 H | 2.64 kg | 11.5 | 14 | 15 | 17 | 18 |

| 22 | Channel | 365 x 20 x 20 | - | 14 | 14 | 14.5 | 16 | 16 |

Industries using Permanent Magnetic Cross Belt Separators:

- Recycling

- Mining and minerals

- Food processing

- Steel and slag processing

- Ceramic and powder

- Wood processing

- Aggregate and quarrying

- Packaging

- Power stations

- Plastic and glass manufacturing

- Pharmaceutical etc.

Why PML?

- Over 45 years of experience in permanent magnet and system design.

- Custom magnetic systems tailored to client needs.

- Excellent after-sales support, including calibration and audits.